WHO WE ARE

Solving Unique

Manufacturing Challenges

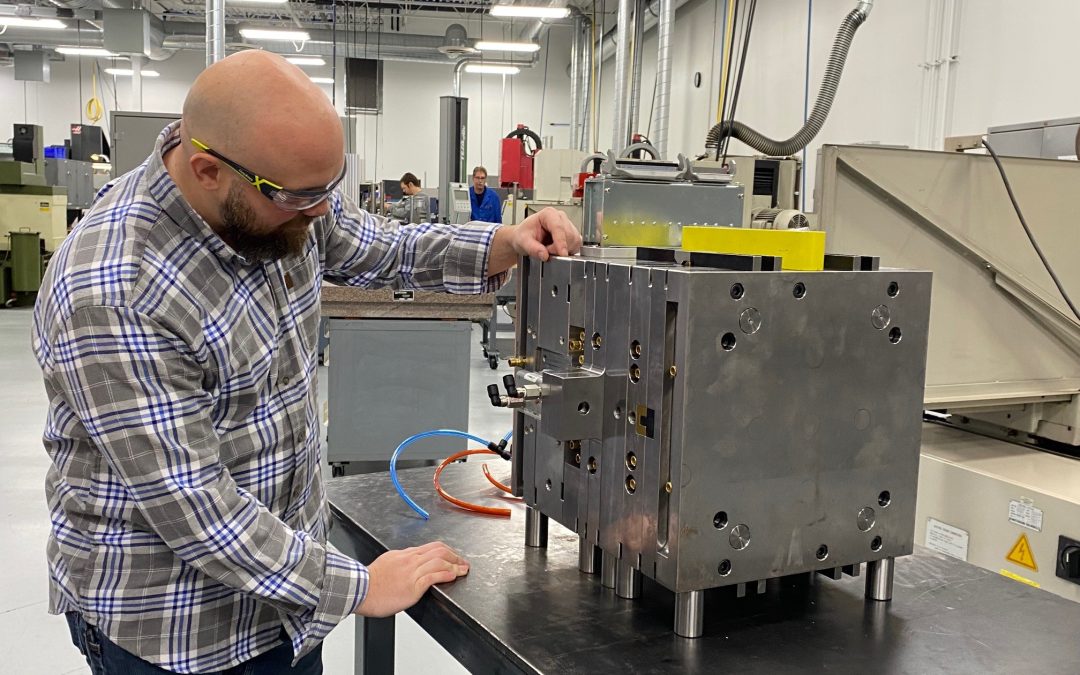

With nearly 600 employees across four facilities, Velosity is the industry leader in state-of-the-art custom contract manufacturing, injection molding, precision machining, and tool building for complex and highly regulated applications. Backed by more than 60 years of experience, Velosity offers a comprehensive range of manufacturing capabilities, bolstered by the latest technologies and a dedicated team of expert engineers and technicians.

We specialize in solving our customers’ most complex manufacturing challenges through creative, customized solutions. As a vertically integrated contract manufacturer, the Velosity family of companies offers proven expertise for medical device and defense manufacturers seeking a reliable, end-to-end partner.

Partnering with Velosity means accelerating the delivery of innovative solutions in both medical device and defense manufacturing. Our deep expertise ensures the quality, reliability, and precision your program demands. Contact us to discover how Velosity can bring unmatched support and collaboration to your next project.

Contract Manufacturing

Injection Molding

Precision Machining

Tool Design & Manufacture

Design Support & Engineering

Tool Sampling & Process Development

Program Transfer

Technology Transfer

Quality Assurance

MARKETS

Specializing in Highly

Regulated Markets

Velosity has the knowledge, certifications, clean rooms, and cutting edge equipment to make complex, highly-specialized products for high-compliance industries. From collaboration in the pre-design phase all the way through product delivery our dedicated team of engineers, technicians, and solution architects is ready to take on your most challenging projects.

RESOURCES

Meet Your Innovation Partner

Find more information about Velosity in our Case Studies, White Papers, and Brochures, or stay up-to-date by following our News & Events section.

Media Kit

PDFs

Videos

Velosity Announces Opening of New Lab, Educational Speakers at MD&M West

FOREST LAKE, Minn. (January 27, 2026) – During this year’s MD&M West, Velosity – the industry leader in state-of-the-art custom contract manufacturing, injection molding, precision machining and tool building for highly regulated devices – announces the launch of...

Tooling Brochure

For unparalleled quality, performance, and design, trust Velosity – the industry leader in designing and building...

PEEK and Titanium Spinal Spacer System

Solution Profile Velosity was challenged by a long-time customer to design, develop and qualify a complete manufacturing process for a thoracic spinal implant system that incorporates the molding of two additive manufactured titanium plates and consists of 75 size...

Program Transfer: A Proven Process

Executive Summary This white paper explores the best practices for a successful program transfer process. [hubspot_form text="Download Velosity Program Transfer White Paper"...

CONTACT VELOSITY

We Look Forward To Hearing From You

Our experienced and helpful staff is waiting to hear from you. Fill out this form and include a short message about how we can help you succeed with your next project.

Be sure to follow us on LinkedIn and signup to receive our newsletter.